Explore

- Home

- About Us

- Services

- Blog

- Contact Us

Quick links

- Guide to Import

- Guide to Export

- ICEGATE

- DGFT

- Get DSC

The global transition toward cleaner energy and the proliferation of electronic devices have made batteries an essential part of our daily lives. Whether in electric vehicles (EVs), mobile phones, laptops, solar energy systems, or industrial machinery, the use of batteries has grown exponentially in India. However, with this surge comes the environmental challenge of managing spent or waste batteries.

In response, India has implemented the Battery Waste Management Rules, 2022, under the umbrella of Extended Producer Responsibility (EPR). These rules place the responsibility of post-consumer battery management on producers, including manufacturers, importers, assemblers, and brand owners. The primary aim is to ensure that batteries are collected, recycled, or refurbished in an environmentally sound manner.

For businesses engaged in the import and export of battery-operated products, understanding and adhering to EPR Battery Waste compliance is critical. This article provides an in-depth, comprehensive guide to EPR for battery waste in India, its implications, compliance framework, challenges, and how a professional compliance services company can help.

Extended Producer Responsibility (EPR) is a policy mechanism that holds producers accountable for the lifecycle of their products, particularly at the post-consumer stage. It ensures that companies which introduce batteries into the market are also responsible for their collection, recycling, and disposal. The rationale behind EPR Battery Waste lies in shifting the burden of waste management from government entities to private producers, thereby promoting a circular economy.

India’s adoption of EPR Battery Waste is aligned with its broader environmental goals, including commitments under the Paris Agreement and the Sustainable Development Goals (SDGs). By enforcing EPR, India aims to reduce hazardous waste, prevent environmental pollution, and recover valuable resources from used batteries.

The Battery Waste Management Rules, 2022 were issued by the Ministry of Environment, Forest and Climate Change and replaced the earlier 2001 regulations. The updated framework includes:

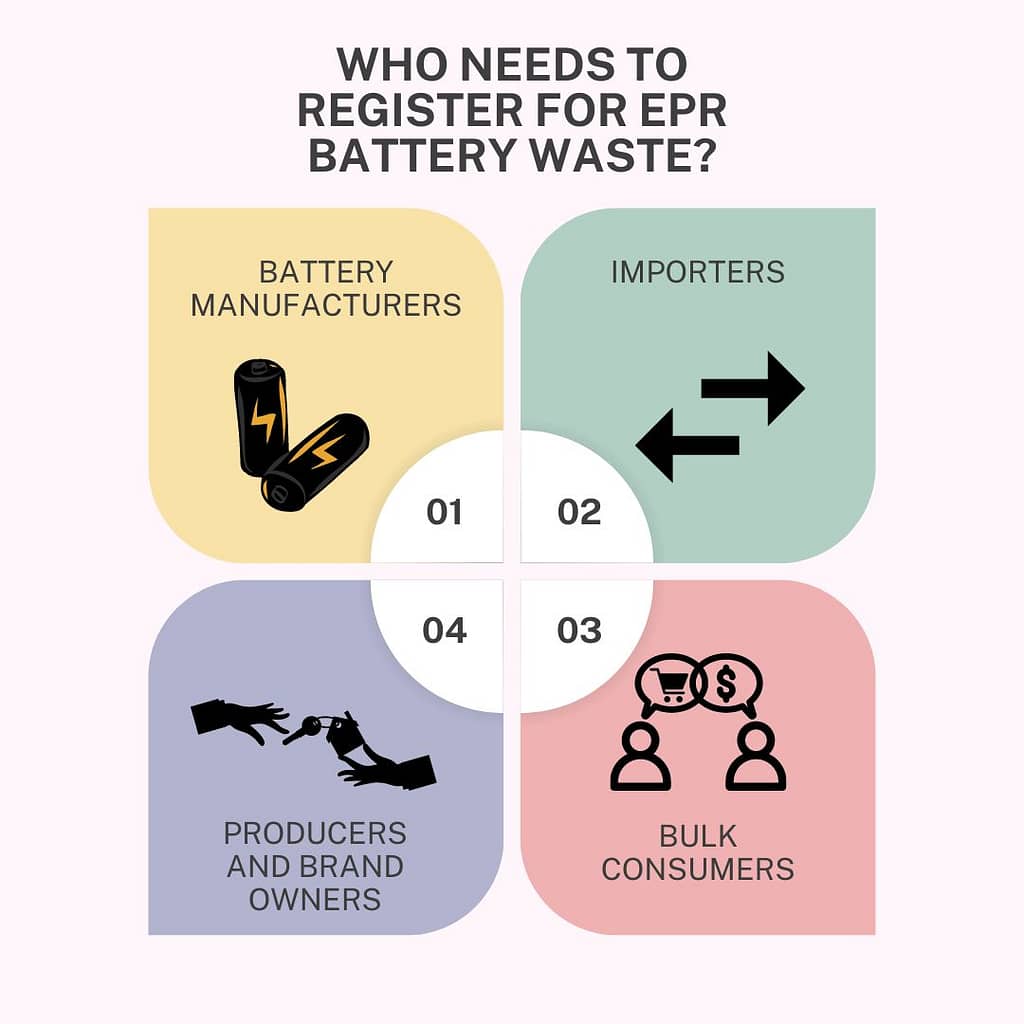

EPR Battery Waste compliance applies to a wide range of stakeholders. Understanding your role under the rules is essential:

This includes manufacturers, assemblers, importers, and brand owners placing batteries or battery-containing products in the Indian market. They must register with the CPCB, declare battery quantities, and meet collection and recycling targets.

Recyclers must obtain authorisation from SPCBs/CPCB and follow environmentally sound recycling practices. They must issue recycling certificates that producers can submit as proof of compliance.

Entities that extend the life of used batteries through refurbishment must also register and follow operational protocols defined by the CPCB.

Entities that use large volumes of batteries must ensure proper disposal through collection points and avoid mixing battery waste with general solid waste.

These are the customer-facing intermediaries who must facilitate take-back mechanisms and educate consumers on responsible battery disposal.

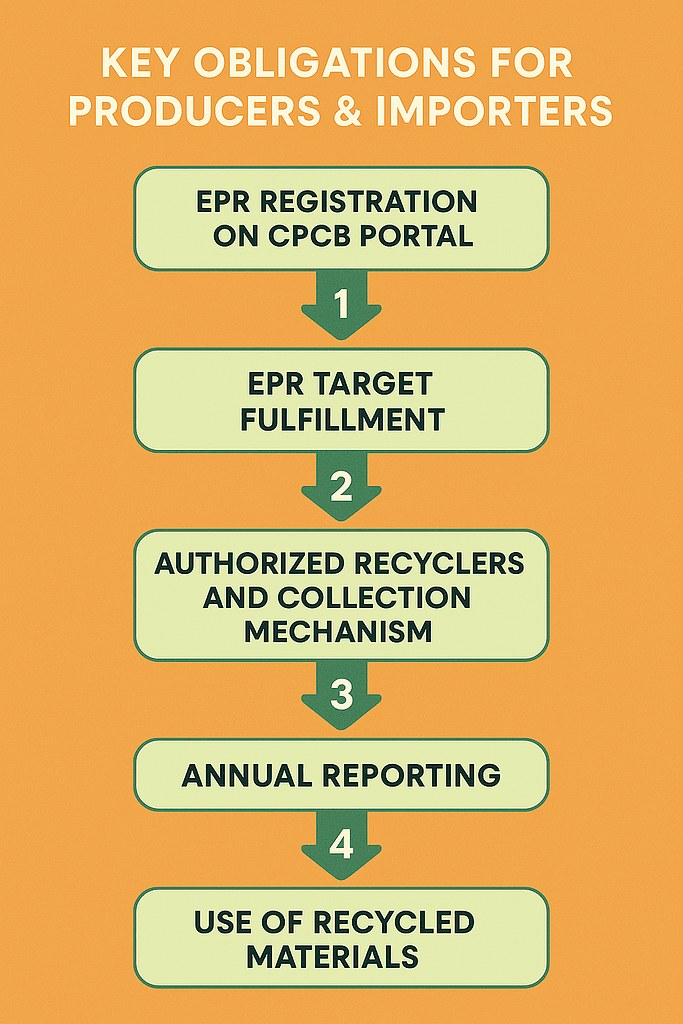

All producers, including importers, must register with the Central Pollution Control Board (CPCB) via the Battery Waste Management EPR Portal. Without registration, sale or import is illegal.

Importers are assigned collection and recycling/refurbishing targets based on the quantity and type of batteries placed on the market.

Producers must ensure that collected batteries are processed only through authorized recyclers and refurbishers.

Detailed reports need to be filed yearly to demonstrate compliance with collection and recycling targets.

New batteries must contain a minimum percentage of recycled materials recovered from waste batteries.

Typically used in handheld devices such as remote controls, cameras, and mobile phones. These are often the most widely disposed of and represent a challenge due to their small size and mixed chemical compositions.

Used in conventional fuel vehicles, primarily lead-acid batteries. These batteries are bulky and contain highly toxic lead, necessitating proper collection and recycling.

Large capacity batteries used in backup systems, energy storage, and solar grids. These are often reusable and need specialised recycling.

Comprising lithium-ion chemistry, these batteries are complex and expensive. Their EPR Battery Waste management requires dedicated logistics and safety protocols.

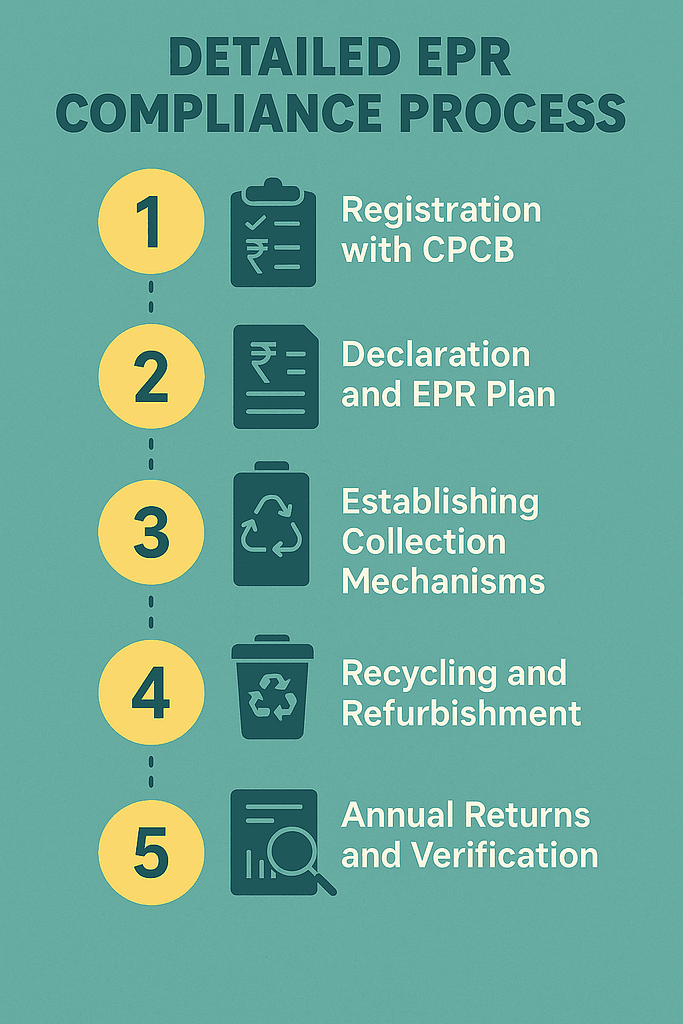

Before placing batteries in the market, producers must register on the CPCB portal, providing PAN, GST, IEC, authorised signatories, and category details of batteries.

Producers must declare the total quantity (by weight) of batteries introduced in the market each year. Based on these quantities, CPCB calculates the target collection obligation for the current and following years.

To fulfill EPR Battery Waste obligations, producers must:

Collected batteries must be sent to certified entities. Recyclers/refurbishers issue digital certificates confirming the quantity and type of waste processed, which producers upload on the portal.

At the end of every compliance year, producers must file an annual report that includes:

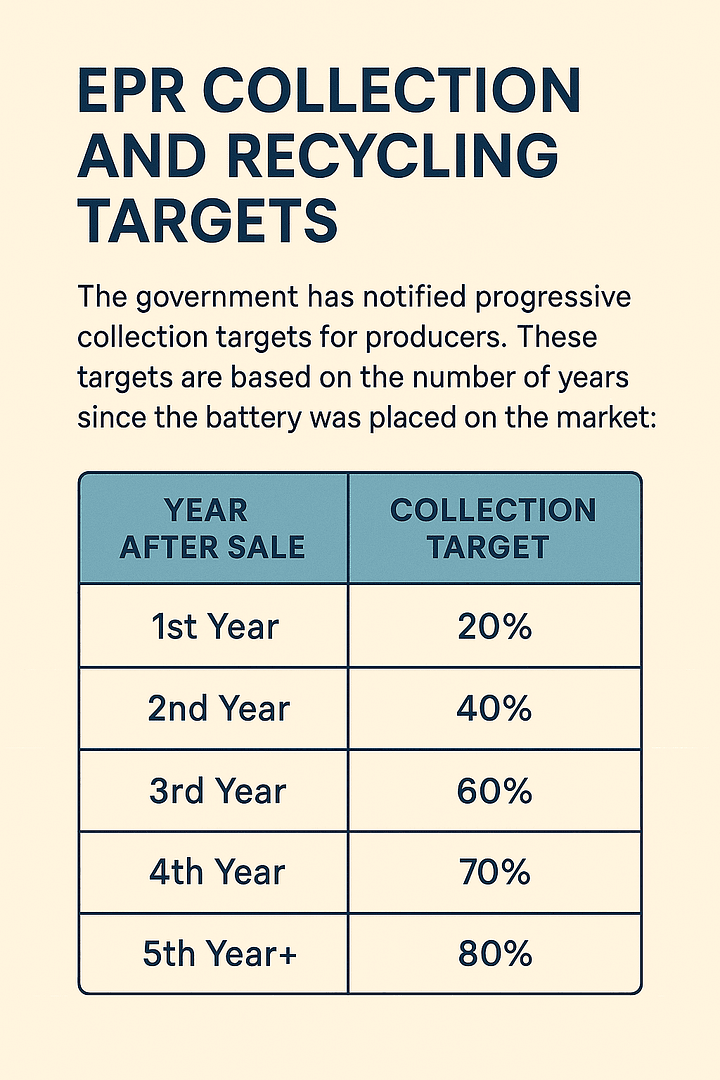

The government has notified progressive collection targets for producers. These targets are based on the number of years since the battery was placed on the market:

| Year After Sale | Collection Target |

| 1st Year | 20% |

| 2nd Year | 40% |

| 3rd Year | 60% |

| 4th Year | 70% |

| 5th Year+ | 80% |

The obligation includes recycled content benchmarks — for example, by Year 5, a lithium-ion battery must include at least 25% of lithium sourced from recycled materials.

Under the rules, every battery and battery product must be labeled with:

Additionally, producers are required to run awareness programs to educate users about hazards of improper disposal and the benefits of recycling.

Non-compliance attracts environmental compensation, calculated per kg of shortfall in meeting targets. For instance:

CPCB may also suspend the registration of habitual violators and publish their names on public portals. Legal action can be initiated under the Environment (Protection) Act, 1986.

Many products (toys, electronics) contain non-removable batteries. Identifying, quantifying, and accounting for these embedded units is complex.

Solution: Use product design databases and supplier declarations to estimate battery volumes accurately.

Tier 2 and Tier 3 cities lack authorised recyclers, limiting collection.

Solution: Partner with national logistics providers to set up temporary collection points.

Matching sales, collection, and recycling certificates is often error-prone.

Solution: Use compliance management platforms with real-time dashboards and automated matching tools.

As a leading import-export and compliance services company, at JPARKS we offer comprehensive assistance:

India’s EPR rules are evolving. Future changes may include:

Global harmonisation with the EU’s Battery Regulation and the U.S. EPA’s framework is expected. Companies investing in EPR now will be best positioned to lead in a resource-scarce, compliance-intensive world.

EPR for battery waste is no longer a choice — it’s a legal mandate and a business imperative. Importers, manufacturers, and brand owners must embrace compliance not only to avoid penalties but to contribute to a greener, more sustainable economy. With strategic planning and the right compliance partner, navigating EPR Battery Waste can become a streamlined and value-generating process.

Importers must separately declare each battery chemistry and category (e.g., portable, industrial) in their EPR filing. The CPCB portal allows multiple entries per product batch. Documentation should be supported by OEM datasheets and customs classification records to avoid misreporting.

No, batteries re-exported within India’s customs territory are not counted toward domestic EPR obligations. However, producers must maintain documentary evidence (e.g., shipping bills, export invoices) to prove re-export. For refurbished units sold in India, EPR continues to apply unless explicitly exempted.

Yes, but only with authorised recycler integration. Some CPCB-authorised recyclers provide API-based digital compliance tracking, allowing producers to match real-time recycling progress with their obligations. Manual validation is still required before uploading final returns.

Even if a producer sells via online platforms, the legal liability for EPR Battery Waste lies with the brand owner or importer who places the product on the Indian market—not the marketplace. However, marketplaces may ask sellers for EPR registration proof as part of their due diligence.

These are classified as industrial batteries under the Battery Waste Management Rules. EPR Battery Waste obligations include separate collection, bulk transportation, and recycling via specialised recyclers. Producers must provide collection options for remote and off-grid locations where solar batteries are typically deployed.

Yes. Even captive or in-house use by a business qualifies as ‘placing on the market’ under EPR Battery Waste rules. These entities must register and fulfill collection/recycling obligations unless they prove complete internal lifecycle control and disposal via authorised recyclers.

Each legal entity with a unique IEC/GST must register separately on the CPCB EPR portal. Aggregated reporting is not permitted unless formally merged under law. Coordination across group companies is essential to avoid duplicate or missing entries.

Producers must still fulfill collection obligations, even for low-volume, single-use batteries. Strategies include:

CPCB requires digitally signed recycling certificates from authorised recyclers/refurbishers. These certificates are verified against the recycler’s processing capacity and quarterly return filings. Random inspections and waste traceability audits may be conducted to prevent fraudulent reporting.

No. Offsetting across battery categories is not allowed. EPR obligations must be met independently for each battery type and chemistry as declared during registration. Surplus in one category cannot compensate for a shortfall in another.

EXCELLENTTrustindex verifies that the original source of the review is Google. Had a really good experience with JParks India. Rahul sir helped me a lot with my import work and were always active and responsive. Whatever documents or guidance was needed, they handled everything smoothly and explained things clearly. Felt stress-free throughout the process. Very helpful team, definitely recommend them if you’re doing import or export.Posted onTrustindex verifies that the original source of the review is Google. Quick & reliable servicePosted onTrustindex verifies that the original source of the review is Google. I took import consultancy services from Mr. Rahul at Jparks India Private Limited, and I must say he has excellent knowledge of the process. Really appreciate his professionalism and support. highly recommended!Posted onTrustindex verifies that the original source of the review is Google. very prompt and authentic services. team very responsive and courteous.Posted onTrustindex verifies that the original source of the review is Google. Wonderful Service and Very Fast. Love to recommend everyone. Thank youPosted onTrustindex verifies that the original source of the review is Google. I can get your import and export support in the future and I need it...I hopePosted onTrustindex verifies that the original source of the review is Google. Good service and posstive resposePosted onTrustindex verifies that the original source of the review is Google. Words fastest service for IEC Certificate and many for your Business They really understand client problem.Posted onTrustindex verifies that the original source of the review is Google. I found Mr Rahul Kolge quite professional & ethicalPosted onTrustindex verifies that the original source of the review is Google. Very Good and prompt response by the team and the work was completed in A day Appreciate itVerified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more