Explore

- Home

- About Us

- Services

- Blog

- Contact Us

Quick links

- Guide to Import

- Guide to Export

- ICEGATE

- DGFT

- Get DSC

If you’re importing raw materials or capital goods worth crores every month, you’re likely facing a significant working capital challenge. MOOWR eliminates this burden by allowing you to defer customs duties until goods are sold domestically—or pay zero duty if you re-export.

Here’s what this means in real terms:

Whether you’re in electronics, automotive, pharmaceuticals, or precision engineering, MOOWR transforms duty payments from a cash-flow killer into a manageable, deferred cost.

The last decade has been transformative for India’s industrial landscape. Domestic firms faced increasing prThe last decade has been transformative for India’s industrial landscape.

Domestic firms faced increasing pressure to be globally competitive, while international companies tested India as a manufacturing and sourcing hub. For businesses dependent on imports, this created an urgent need: a duty-deferment mechanism that didn’t lock them into export obligations or geographic zones.

MOOWR emerged as the solution—a neutral, obligation-free, location-free, all-sector-inclusive scheme that reduces manufacturing costs and frees up working capital.

If you’re an importer or manufacturer looking to eliminate upfront duty payments while maintaining complete operational flexibility, this guide explains everything you need to know—and how JPARKS can help you get approved.

To understand MOOWR entirely, we must trace how India managed bonded manufacturing before 2019 – and why the 2019 overhaul was so significant.

Bonded manufacturing under Sections 58 and 65 of the Customs Act existed long before MOOWR. However, it remained largely unused due to structural issues:

The old bonded system was:

A manufacturer was expected to maintain input–output norms, follow strict wastage accounting, and operate under the physical supervision of customs officers.

For domestic manufacturers, these restrictions made the scheme almost unusable.

Most businesses found the old system impractical because:

As a result, even though the law technically allowed bonded manufacturing, industries stayed away.

Recognizing these shortcomings – and India’s growing participation in global manufacturing value chains – the government completely revamped the system in 2019.

The new framework:

Manufacturing and Other Operations in Warehouse Regulations, 2019

commonly called MOOWR, was introduced. This transformation brought three major shifts:

The earlier dependence on on-site customs presence was eliminated.

Inventories now rely on:

Businesses no longer needed to export or commit to foreign markets. Domestic manufacturers could avail the same benefits without shifting to SEZs.

The earlier system had multiple approvals and extensive reporting.

MOOWR reduced this to:

This modernized framework aligned India with global best practices in warehouse-based manufacturing.

COVID-19 accelerated global supply-chain diversification. Companies across the world began looking for alternatives to China.

MOOWR gained traction because it offered:

Industries such as electronics, semiconductors, EVs, aerospace, pharmaceuticals, renewable energy, and precision engineering became major adopters. In effect, MOOWR became India’s closest equivalent to a free-trade-zone concept – but without requiring a designated zone.

MOOWR is not just a tax measure – it is a strategic economic reform aimed at strengthening India’s manufacturing ecosystem. Its objectives are both macroeconomic and operational.

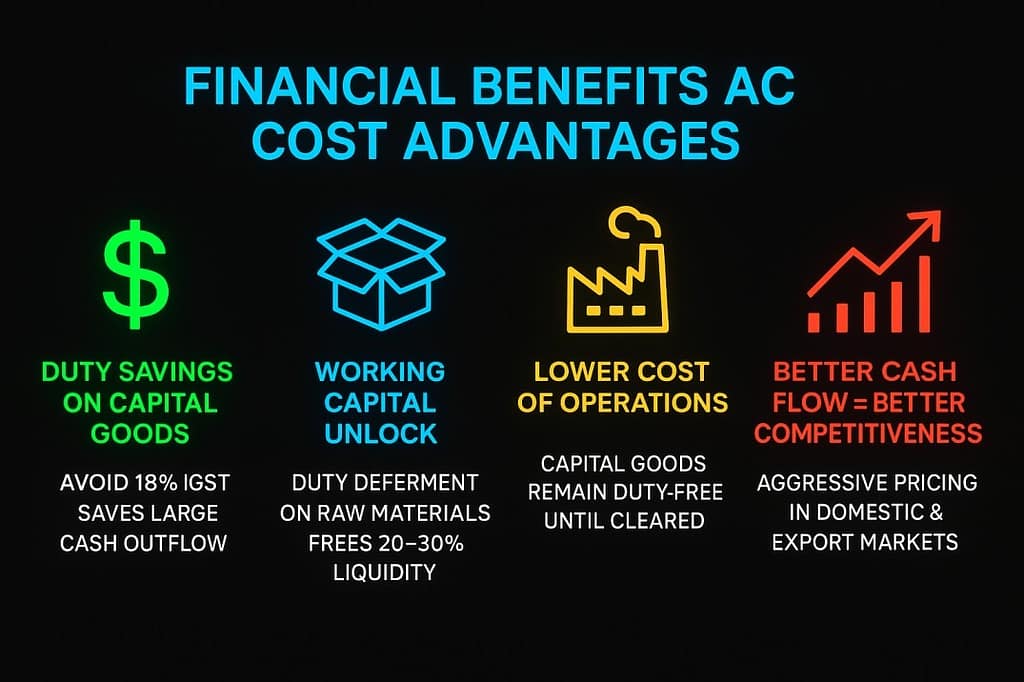

Importing capital goods (machinery, equipment, analytical devices) usually triggers heavy IGST payments – often 18 percent or more.

MOOWR eliminates this upfront burden by exempting IGST on capital goods used inside the warehouse. This dramatically reduces initial project cost and encourages:

Working capital is a major operational constraint, especially for industries relying on imported inputs.

MOOWR resolves this by deferring customs duties (BCD, Cess, Safeguard Duties, IGST) until goods are cleared for domestic sale. If goods are re-exported, duty becomes zero. This frees up liquidity that businesses can use for:

One of MOOWR’s biggest advantages is its resemblance to international bonded manufacturing frameworks. The scheme enables:

Companies can build global supply chains while manufacturing within India, reducing costs and increasing speed.

Unlike PLI, SEZ, or EPCG, MOOWR:

It is a simple, rules-based, compliance-based framework rather than a subsidy scheme.

Understanding the legal foundation is important for any business planning to adopt MOOWR.

The scheme relies on three layers:

The Customs Act, 1962 contains the enabling provisions:

Section 58

Grants licences to private bonded warehouses.

Section 65

Allows businesses to undertake manufacturing or other operations within such warehouses.

The following regulations govern actual operations:

These regulations detail record-keeping, bond requirements, inventory systems, security norms, and returns.

A MOOWR warehouse is:

In essence, the government provides fiscal freedom but retains risk-based oversight.

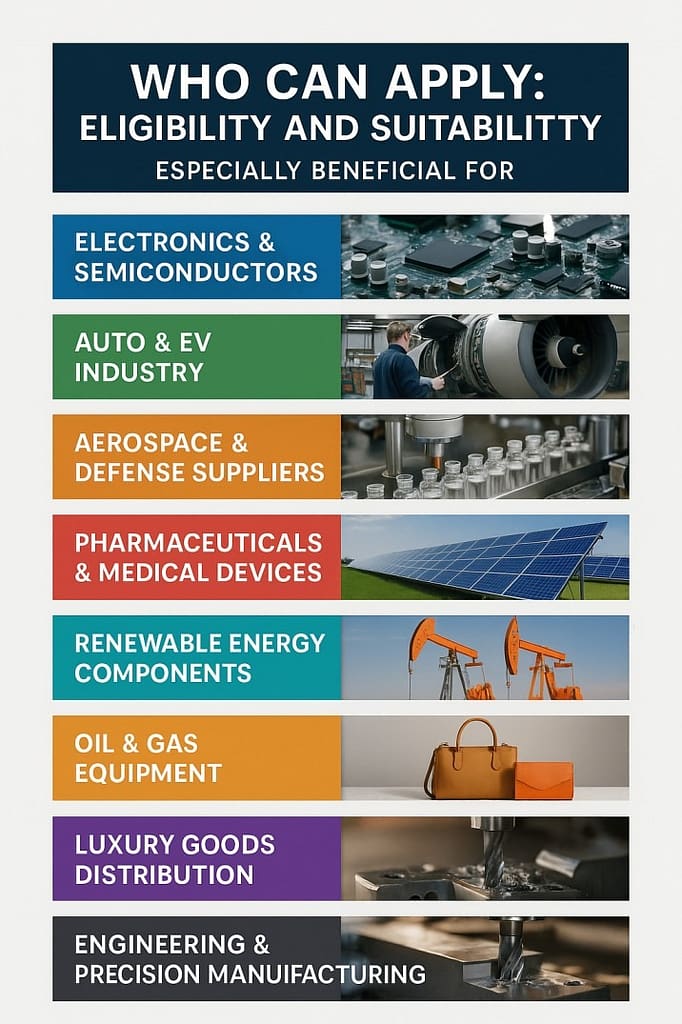

One of MOOWR’s biggest strengths is its universal accessibility.

Any business – from an MSME importer to a multinational manufacturer – can apply.

There is no threshold for:

MOOWR is not limited to traditional “manufacturing” industries. It supports:

Even high-value trading operations can participate.

High dependency on imports and high capital goods cost makes MOOWR extremely beneficial.

Battery cells, semiconductor chips, converters, motors, and controllers often form 50–60 percent of input cost and attract heavy duties.

MOOWR helps companies importing precision parts and machinery avoid massive upfront duties.

APIs, reagents, high-end diagnostic equipment, and analytical instruments become much more affordable.

Businesses dealing with solar modules, hydrogen equipment, wind turbine parts benefit substantially.

High-value components and tooling imports see large cash-flow advantages.

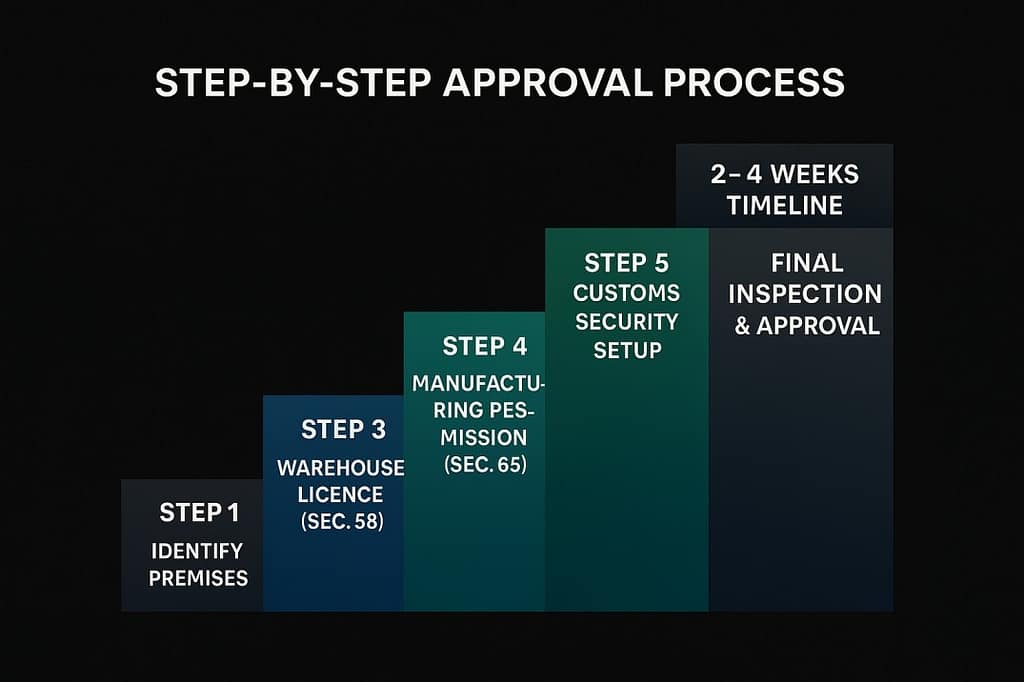

The process is straightforward but requires documentation and security readiness.

A warehouse or manufacturing unit, owned or leased, must be designated as a bonded space. The layout must support:

Businesses submit:

The customs authority ensures the premises can operate securely under MOOWR norms.

This includes detailed operational documentation:

This ensures transparency in operations.

A bond equal to three times the duty payable on goods to be stored must be executed.

The bond acts as financial security for the government in case duties are not paid during domestic clearance.

This includes:

Customs may visit the premises to verify layout, security, and documentation.

Once approved, the warehouse receives:

Typical processing time: 2–4 weeks depending on the customs zone and completeness of documentation.

The MOOWR approval process involves multiple documentation requirements, security standards, and customs coordination. JPARKS handles this end-to-end:

What we do for you:

Timeline: JPARKS typically secures MOOWR approval within 2-4 weeks, depending on customs zone responsiveness.

Call +91 9167379073 or fill out the form below to start your application.

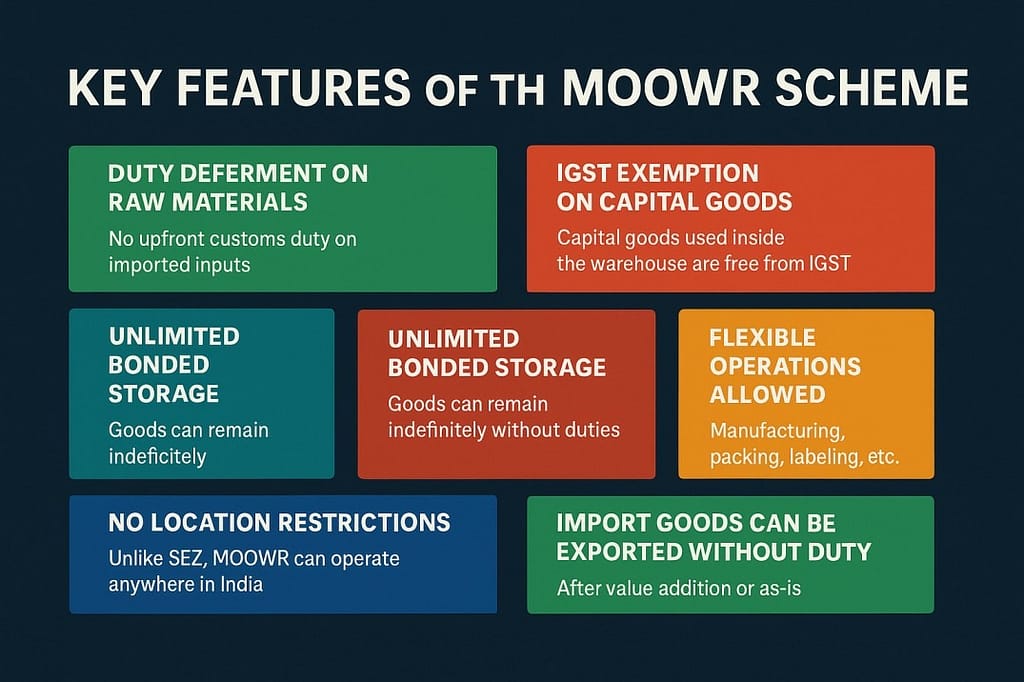

MOOWR provides a combination of benefits unmatched by any other Indian manufacturing incentive scheme.

Businesses do not pay:

until goods are removed for home consumption.

If re-exported, duties are waived entirely.

Capital goods installed inside the warehouse enjoy full IGST exemption, reducing project setup costs significantly.

MOOWR does not require:

Companies can sell 100 percent domestically without penalty.

Goods can remain in the bonded warehouse indefinitely, giving companies unmatched flexibility for:

MOOWR allows activities such as:

This allows companies to modify goods as required before sale.

Any facility anywhere in India can be approved.

This is a major advantage compared to SEZs, which require businesses to relocate.

Goods can be exported:

Financially, MOOWR provides unmatched savings.

Importing machinery under MOOWR eliminates IGST payments that usually amount to:

This reduces capital cost, borrowing need, and depreciation base.

For companies importing raw materials worth crores every month, paying customs duties upfront creates significant financial strain.

MOOWR allows duties to be paid only when goods are sold domestically, not when they enter India.

This improves:

Lower working capital burden reduces interest costs and improves net margins.

This allows companies to price competitively in both domestic and international markets.

Businesses can import in bulk during price dips or supply-chain disruptions and store inputs indefinitely without duties.

Despite its benefits, MOOWR requires responsible record-keeping and security.

Businesses must file a monthly return detailing:

A real-time system must track:

This ensures accurate reconciliation.

Customs may conduct risk-based audits or inspections.

Mandatory:

Businesses must ensure:

MOOWR integrates smoothly with GST provisions.

Raw materials and capital goods imported under MOOWR do not attract IGST upfront.

When goods are finally cleared into the domestic market, GST must be paid — and Input Tax Credit (ITC) is allowed.

Exports do not require payment of IGST or customs duties.

MOOWR units can undertake job work for third parties, subject to permissions.

MOOWR stands out because it avoids obligations and geographical restrictions.

| Feature | MOOWR | SEZ |

| Location restriction | No | Yes, only in SEZ zones |

| Export obligation | None | Yes |

| Domestic sales | Allowed without penalty | DTA sale restrictions |

| Capital goods IGST | Exempt | Exempt |

| Flexibility | Very high | Moderate |

EPCG requires export obligations equal to six times the duty saved.

MOOWR has no such requirement.

FTWZ is trading-focused.

MOOWR supports both trading and manufacturing.

PLI provides cash incentives but only to qualifying sectors.

MOOWR is open to all sectors and offers liquidity benefits without performance conditions.

Electronics manufacturers rely heavily on imported chips, semiconductors, PCBs, and components.

MOOWR reduces:

EV and automotive manufacturing involve:

These components attract high duties. MOOWR helps reduce the cost of production significantly.

Specialized components and long production cycles make duty deferment extremely valuable.

APIs, reagents, and specialized instruments are expensive, and MOOWR helps optimise capital.

Solar and wind components, hydrogen fuel parts, and inverters are often imported.

MOOWR reduces project costs.

Even though MOOWR is flexible, businesses should be aware of practical challenges.

Not all premises meet MOOWR’s security standards.

CCTV and access control systems may require investment.

Monthly filings and inventory discipline require reliable ERP systems.

Some customs zones process applications faster than others.

Banks, auditors, and investors may not fully understand MOOWR’s benefits unless explained.

MOOWR reflects India’s shift toward:

It bridges the gap between:

MOOWR enables India to compete with global manufacturing hubs without creating large, subsidy-heavy systems.

JPARKS India has helped dozens of manufacturers, importers, and exporters unlock the benefits of MOOWR. From initial consultation to final approval, we manage every step of the process.

Why choose JPARKS:

✓ 40+ years of experience in customs and EXIM compliance

✓ End-to-end service: No need to coordinate with multiple agencies

✓ Fast approvals: Average 2-4 week timeline

✓ Post-approval support: Ongoing compliance management available

Get started in 3 steps:

MOOWR is one of India’s most strategically significant manufacturing frameworks. Its combination of duty deferment, IGST exemption, operational flexibility, and no export obligations makes it uniquely powerful for businesses across sectors.

For any company dependent on imports – whether for machinery, raw materials, or high-value components – MOOWR is more than a tax-saving mechanism. It is a strategic tool for achieving:

As India continues positioning itself as a global manufacturing hub, MOOWR will remain central to enabling efficient, sustainable, and competitive industrial growth.

The biggest advantage is that MOOWR has no export obligation at all. Units may sell entirely in the domestic market and still enjoy duty deferment and IGST exemption on capital goods. This makes MOOWR a neutral and flexible option compared to EPCG or SEZ, which require export commitments or specific locations.

Yes. Any existing premises, whether owned or leased, can be converted into a bonded facility once it meets the security and record keeping standards prescribed under the scheme. There is no need to relocate or create a new building.

No. The scheme has no minimum financial thresholds. Small, mid sized and large companies can all apply, making it suitable for a wide range of industries and business sizes.

Duty on capital goods is deferred for as long as the machinery remains inside the bonded premises. Duty becomes payable only if the machinery is removed for use outside the bonded area. If the machinery continues to be used inside the warehouse, the duty remains deferred indefinitely.

Yes. MOOWR imposes no export requirement. Units may sell any amount of their production domestically. Duty applies only on the imported inputs used in goods cleared for home consumption.

GST is not payable at the time of import of raw materials or machinery into the bonded warehouse. GST is charged only when the finished goods are sold within India, and buyers may claim input tax credit as usual. Exported goods have no GST burden.

A MOOWR unit must maintain monthly returns, real time inventory records, proper security of the bonded area, a complete bond register and reconciliation of goods. The compliance system is structured but simpler than earlier bonded manufacturing rules.

Yes. With required permissions, a MOOWR unit may carry out manufacturing or processing for other businesses. It must maintain accurate accounting for incoming materials, production and clearance. This allows the unit to operate as a specialised bonded manufacturing centre.

Yes. The scheme is designed to help both exporting units and domestic focused manufacturers. Any company that imports significant raw materials or machinery can save considerable working capital even without exporting a single product.

There is no time limit. Goods may remain stored in the bonded warehouse indefinitely, which is helpful for industries with long production cycles, unpredictable demand or high value inventories.

The typical timeline is 2 to 4 weeks from documentation submission to final approval. However, this depends on the responsiveness of your local customs zone and the completeness of your premises setup. JPARKS manages all interactions with customs to minimize delays.

You’ll need premises documents (ownership or lease deed), floor plans, details of your manufacturing process, and proposed security infrastructure plans. JPARKS prepares all technical documentation including operational workflows, inventory systems, and reconciliation methodologies on your behalf.

Yes. Beyond securing your MOOWR license, we offer ongoing support including monthly return filing, inventory reconciliation templates, bond renewal reminders, and periodic compliance audits to ensure you remain in good standing with customs.

EXCELLENTTrustindex verifies that the original source of the review is Google. Had a really good experience with JParks India. Rahul sir helped me a lot with my import work and were always active and responsive. Whatever documents or guidance was needed, they handled everything smoothly and explained things clearly. Felt stress-free throughout the process. Very helpful team, definitely recommend them if you’re doing import or export.Posted onTrustindex verifies that the original source of the review is Google. Quick & reliable servicePosted onTrustindex verifies that the original source of the review is Google. I took import consultancy services from Mr. Rahul at Jparks India Private Limited, and I must say he has excellent knowledge of the process. Really appreciate his professionalism and support. highly recommended!Posted onTrustindex verifies that the original source of the review is Google. very prompt and authentic services. team very responsive and courteous.Posted onTrustindex verifies that the original source of the review is Google. Wonderful Service and Very Fast. Love to recommend everyone. Thank youPosted onTrustindex verifies that the original source of the review is Google. I can get your import and export support in the future and I need it...I hopePosted onTrustindex verifies that the original source of the review is Google. Good service and posstive resposePosted onTrustindex verifies that the original source of the review is Google. Words fastest service for IEC Certificate and many for your Business They really understand client problem.Posted onTrustindex verifies that the original source of the review is Google. I found Mr Rahul Kolge quite professional & ethicalPosted onTrustindex verifies that the original source of the review is Google. Very Good and prompt response by the team and the work was completed in A day Appreciate itVerified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more